USA

USA

Latin America

Brazil & Portugal

888-800-2310 (Toll Free) 989-681-2158 (Local/International) 740 E Monroe Road, St. Louis, MI 48880

517-579-3061 Teléfono en México: 55-5351-3093 info@brinechlor.com

55-13-997855697

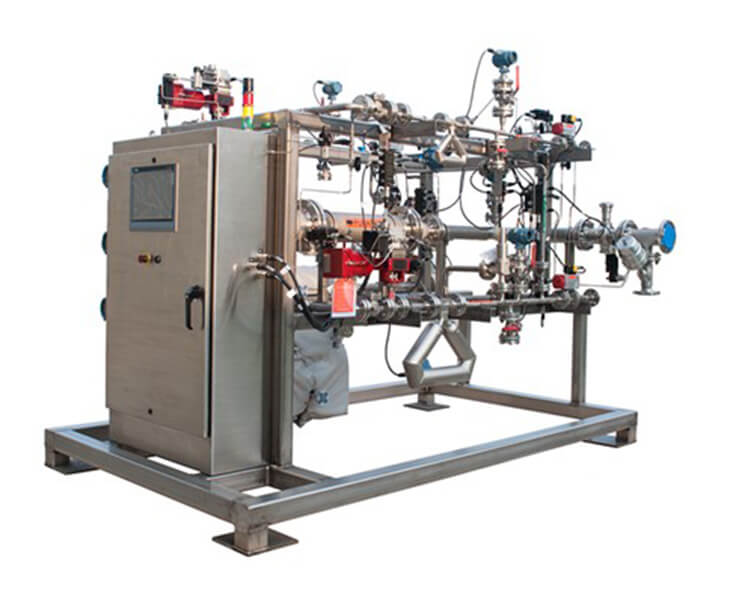

Our Multi-Stream In-Line Mixing & Blending System is a continuous system that can simultaneously mix multiple streams of liquid raw materials with the precision and accuracy needed to produce a wide variety of finished products. The systems are commonly used to mix recipes for automotive coolants, cleaners, detergents, consumer products, diesel exhaust fluid, RV antifreeze, and more. The accuracy and repeatability is superior to batch process methods.

This system comes fully assembled and skid-mounted, complete with controls, piping, valves, and instrumentation. It is engineered for a project specific flow rate, concentration ranges and accommodates blending of multiple raw material streams and any required additives. A properly sized system can reduce the number of necessary storage tanks at a given facility since only concentrated feedstock and water would need to be stored.

The system provides an accurate and repeatable final product allowing for precise product specifications and reduced raw material losses. It is programmed to instantly auto-adjust stream flow rates in the event of a process upset. If the process upset cannot be corrected automatically, the system will stop, protecting pumps and ensuring consistent product quality. The systems shut down upon high or low tank level.

Our systems are supported by our experienced technicians who can provide startup, operator training, or perform scheduled preventive maintenance and calibration. Additional charges may apply for these services.